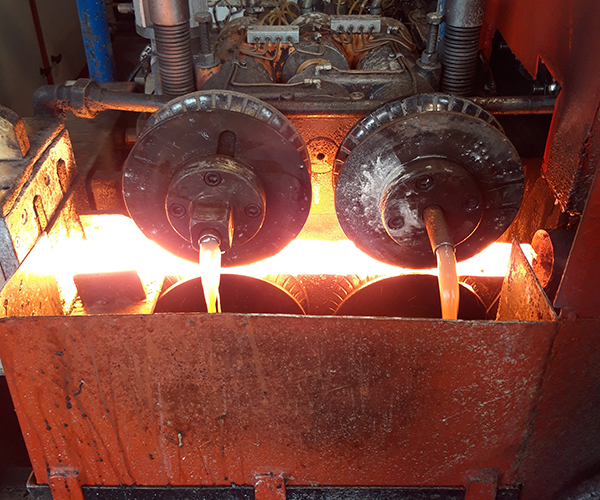

/ HOT FORGING

HOT FORGING

Hot forging process represents first step to guarantee high quality products to our customers.

This process is made thanks to thirty years' experience of our sister company that realises steel and aluminium bungs, neck rings and nuts with a weight from 100 gr to 2/3 kg with a production capacity of more than 100.000 pcs/day.

Steel and aluminium forged parts are made on three different types of press, to better adapt themselves to always more specific customers' demands, both in terms of quantity and of complexity of realization.

Quality of our products is guaranteed also by moulds and equipment produced by technicians in internal workshop.